Dehydration Systems

-

Proven reliability

-

Unmatched expertise

VWM DEHYDRATION SYSTEMS

Since 1946, VWMworks has been building Dehydrators to meet the needs of the Dried Fruit Industry. We feature dried fruit washers, our dried fruit singulator, and dried fruit de-clumper as leading products in this industry. Quality equipment and machinery backed by year round service makes VWM Tunnel Dehydrators unmatched in reliability. VWM builds dehydration systems that are strong, easy to operate, and practical. That is why VWM dehydrators have become the standard of the industry.

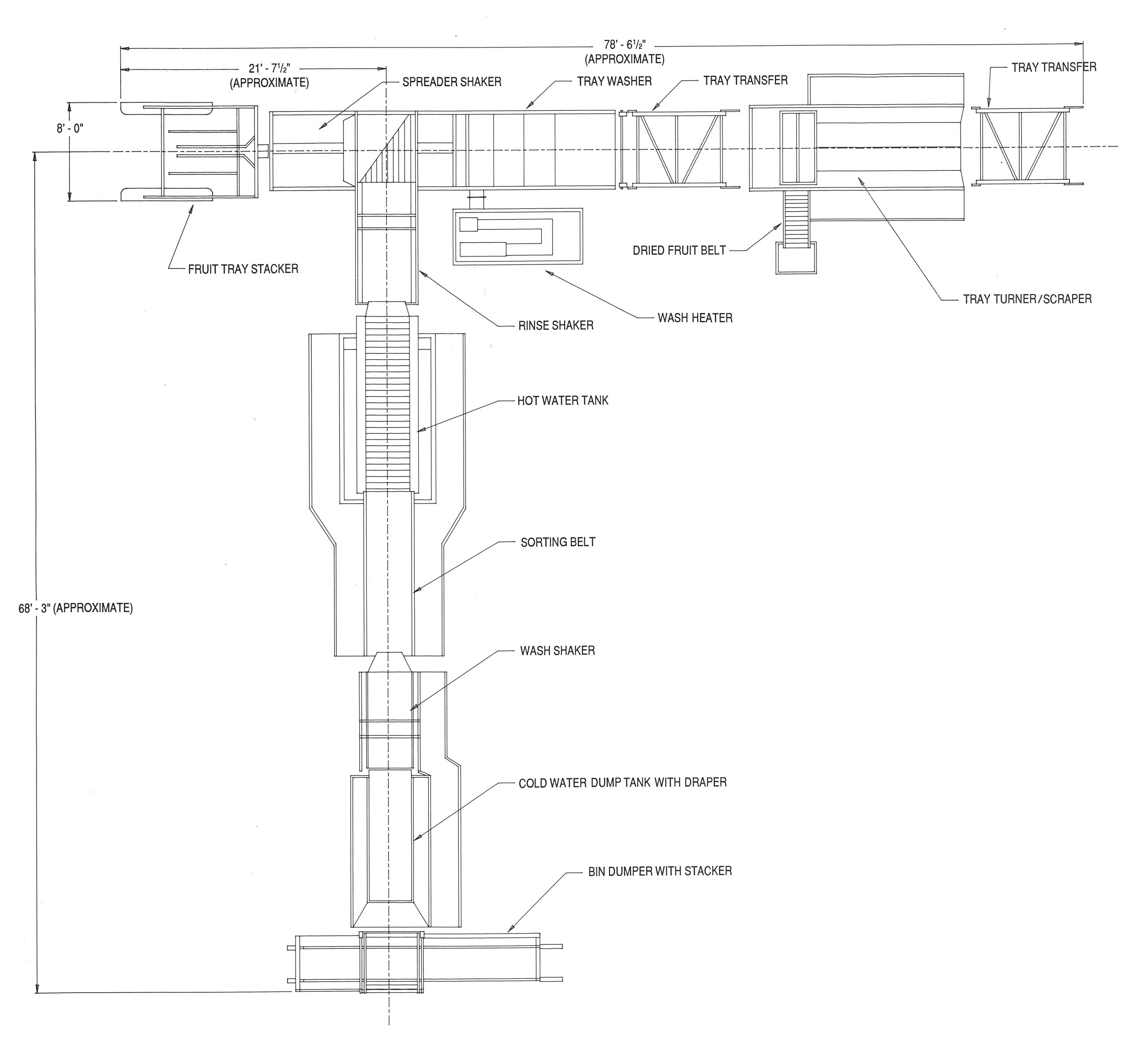

VWM Bin Dumper

This unit is loaded with full bins and hydraulically dumps the product. The optional hydraulic Bin Conveyor and

Empty Bin Stacker offers an efficient bin handling system.

VWM Cold Water Dump Tank With Draper

The Cold Tank offers a metered flow of product via a variable speed, cleated belt while washing the product straight from the bin.

VWM Cold Water Dump Tank With Draper

This unit is equipped with high pressure sprays and a screened bed to wash of any undesirable

material, dirt, debris, etc. All particles washed off are directed into the trash hopper below.

VWM Sorting Belt

This station allows for a visual and hand inspection of product. Equipped with service catwalks on both sides for personnel.

VWM Hot Water Tank

Used for certain products the hot tank offers State-of-the-art burners and controls for regulated heat, when desired.

VWM Rinse Shaker

This unit offers a final spray wash of the product just prior to loading the trays.

VWM Spreader Shaker

This unit is loaded with product from the Rinse Shaker.

Designed with an automatic flip gate, the Spreader Shaker evenly loads the wood trays with product.

VWM Tray Washer

The Tray Washer high pressure sprays the emptied tray on both sides via a stainless steel

pump. The designated hot water tank recycles the water and removes the impurities.

VWM Tray Turner/Scraper

Here dried trays are loaded to allow for the scraping of product off the trays. The turner automatically drops the loose product onto a conveyor that collects into bins.

VWM Tray Stacker

The Tray Stacker automatically stacks the loaded wood trays (25) high onto the fruit

cars, now ready for dehydration. Included in this system is a car pull system that automatically indexes the fruit cars for loading.

Testimonials

Kaz Yamaguchi | Corporation Manager of Fruits & Nuts Dept.

Kaz Yamaguchi | Corporation Manager of Fruits & Nuts Dept.

ShoEi Foods

The machinery we purchase from Valley Welding & Machine Works for our plants in Japan and China is reasonably priced and dependable. We do business with VWMworks because they give us the right information and advice when we need it right away.

Kaz Yamaguchi | Corporation Manager of Fruits & Nuts Dept.

Shoei Foods

The machinery we purchase from Valley Welding & Machine Works for our plants in Japan and China is reasonably priced and dependable. We do business with VWMworks because they give us the right information and advice when we need it right away.

Keith Rigg | General Manager

Minturn Nut Company

Contracting with Valley Welding & Machine Works to build and install our new state-of-the-art processing line was not an easy decision for many reasons. Once Minturn Nut decided to go with Valley Welding & Machine and signed the contract, we never looked back. Valley Welding & Machine Works handled our project with a high level of professionalism and knowledge that gave us the confidence and comfort that Minturn Nut made the best choice. Now that the new line is up and running, the results are proof positive.

Keith Rigg | General Manager

Minturn Nut Company

Contracting with Valley Welding & Machine Works to build and install our new state-of-the-art processing line was not an easy decision for many reasons. Once Minturn Nut decided to go with Valley Welding & Machine and signed the contract, we never looked back. Valley Welding & Machine Works handled our project with a high level of professionalism and knowledge that gave us the confidence and comfort that Minturn Nut made the best choice. Now that the new line is up and running, the results are proof positive.