Advanced Raisin Processing

VWM – The World’s #1 Choice

Maximize your raisin processing line efficiency with VWM Advanced Processing Equipment.

VWM is the world leader in design & manufacturing of raisin processing machinery.

Our equipment has become the industry standard as VWM’s state of the art innovative designs provide the most efficient and effective Raisin Processing Lines available. With over 7 decades of experience in the Raisin Industry, VWM’s commitment to excellence has resulted in processing equipment that produces top quality finished product while maintaining the highest yields and low cost line operation. Start typing.

If you want the best in Raisin Processing Machinery use VWM, specializing in: Complete lines available in a wide range of capacities from 4,000 to 70,000 lbs per hour. VWM specializes in:

- High speed pre scalping systems

- Super Vac stem removal

- Dry Cappers

- Rotation Recleaners

- Dumping And Feeding

- Sugar Coating

- De Clumping

- Size Grading Lines

- Washing Lines

- Automatic Bulk Packaging

A Closer Look at VWM Raisin Processing Lines

These are just a few examples of our highest technology options.

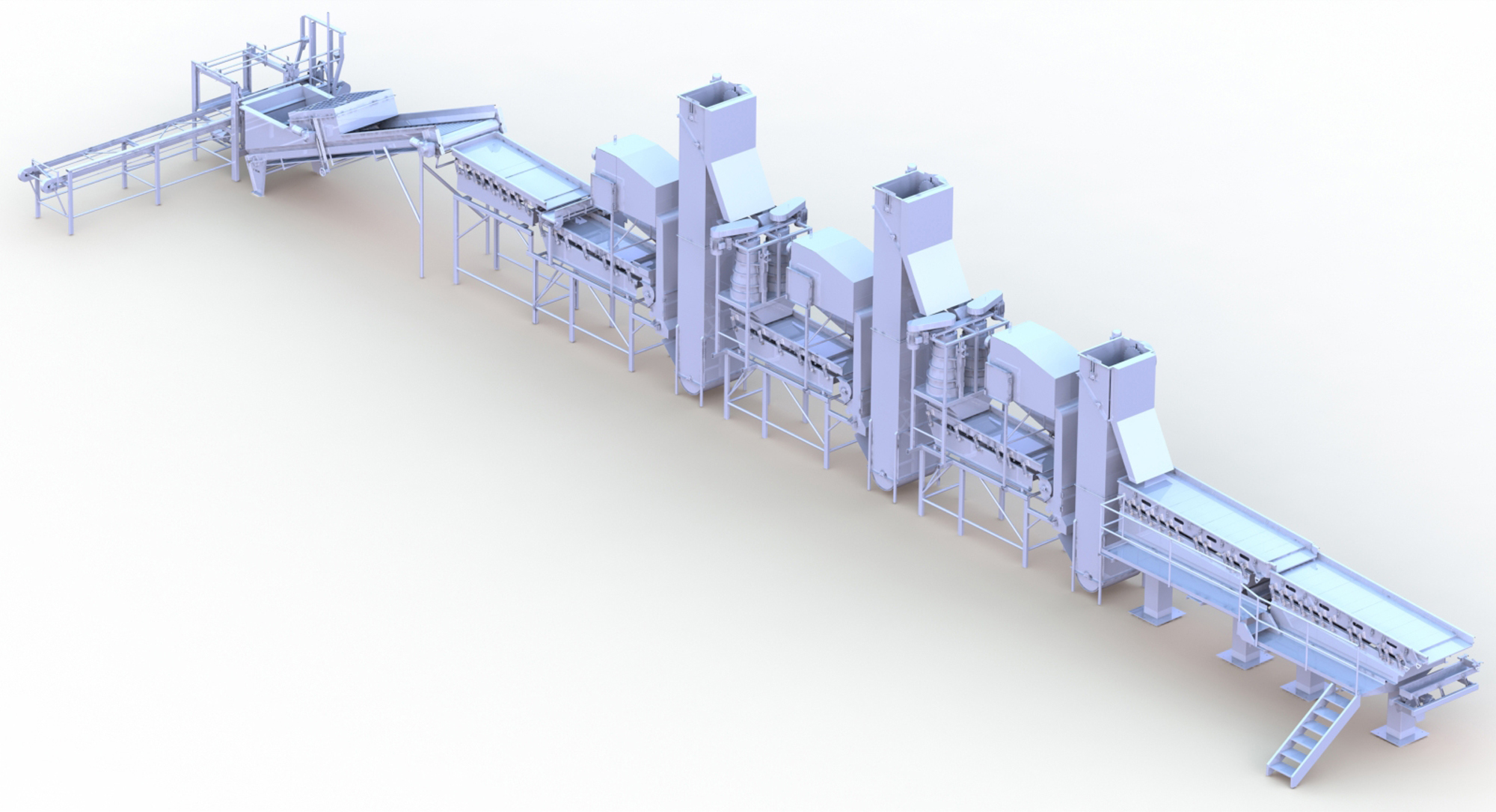

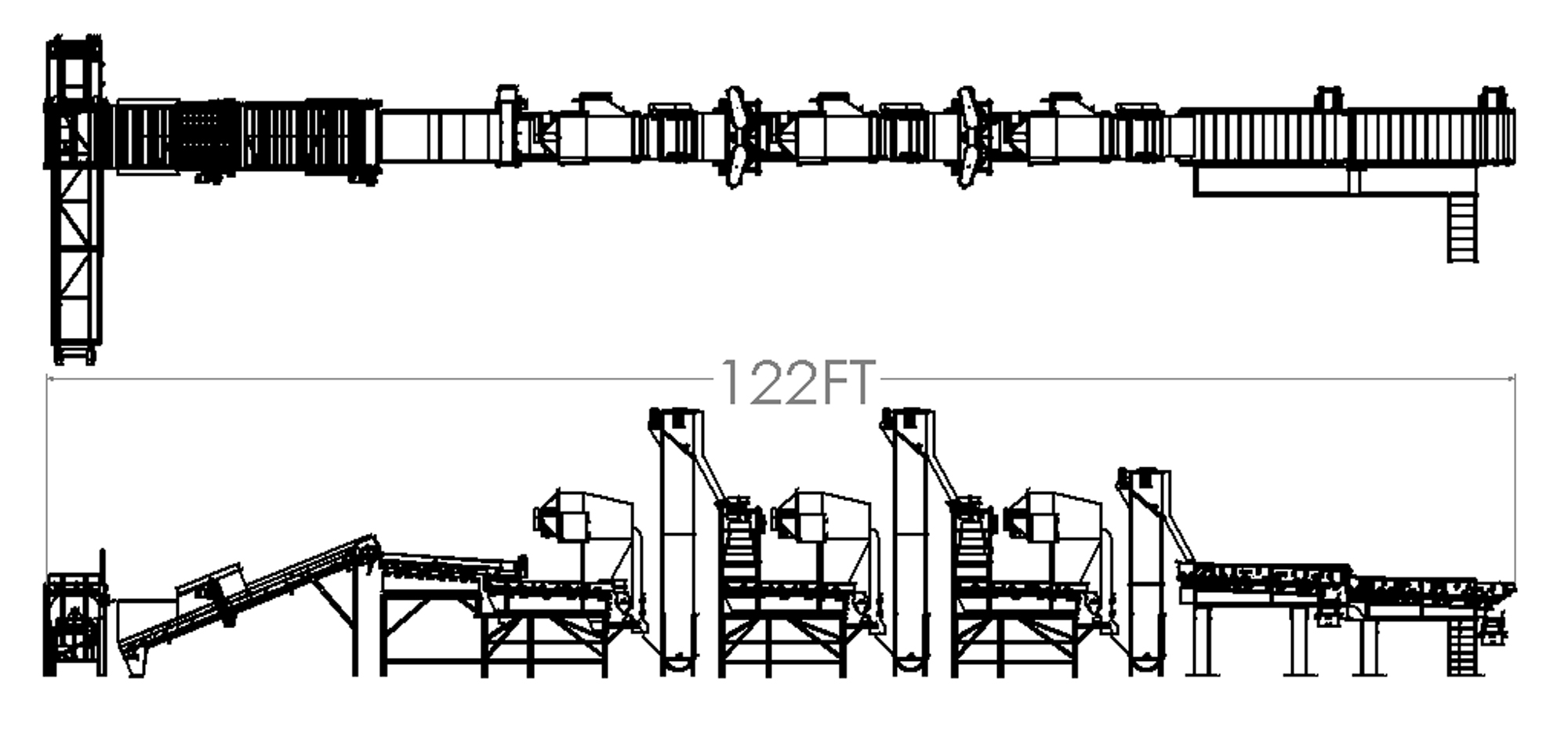

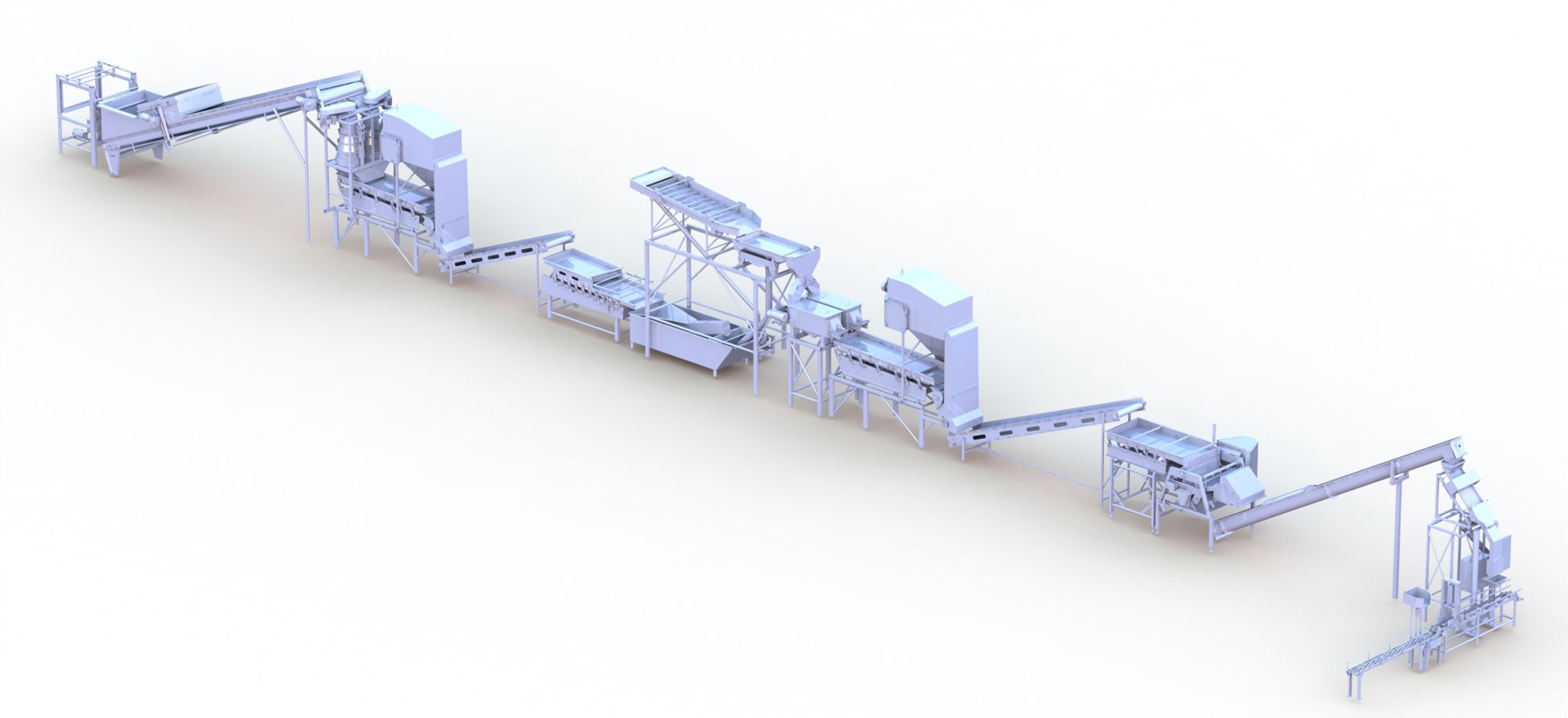

VWM Advanced Raisin Processing Grading Line

The VWM Advanced Raisin Processing Grading Line provides efficient cleaning and sizing. Removal of stems, dirt, and debris are maximized to provide top quality raisins.

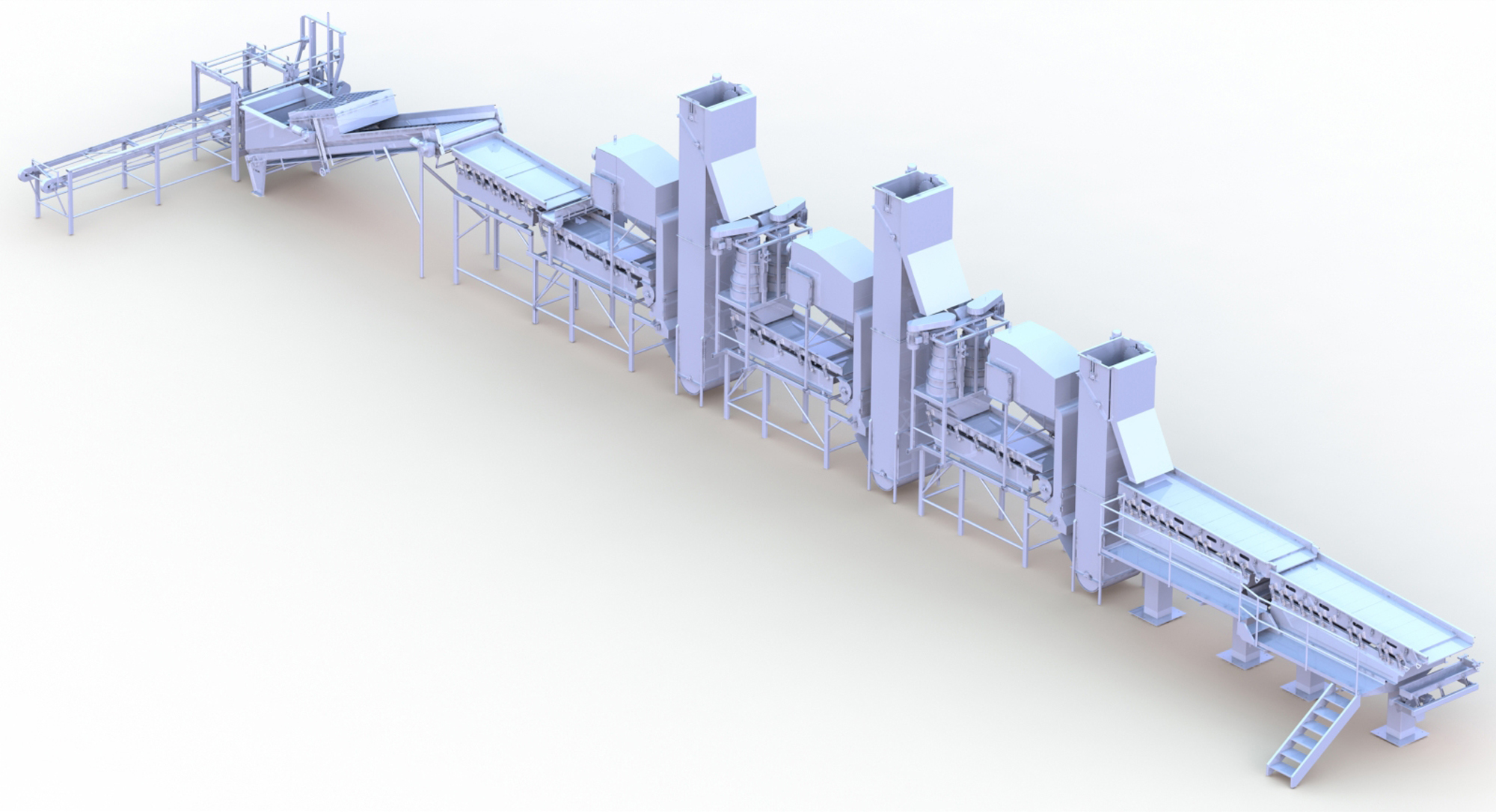

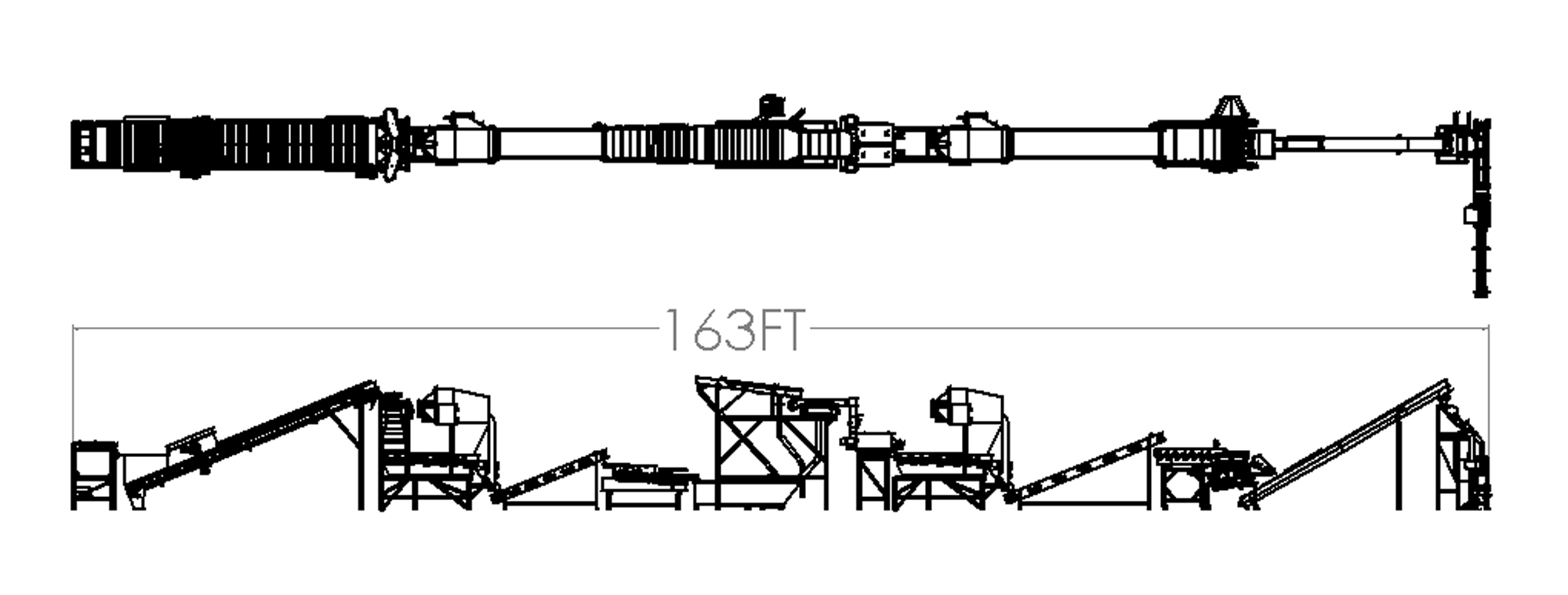

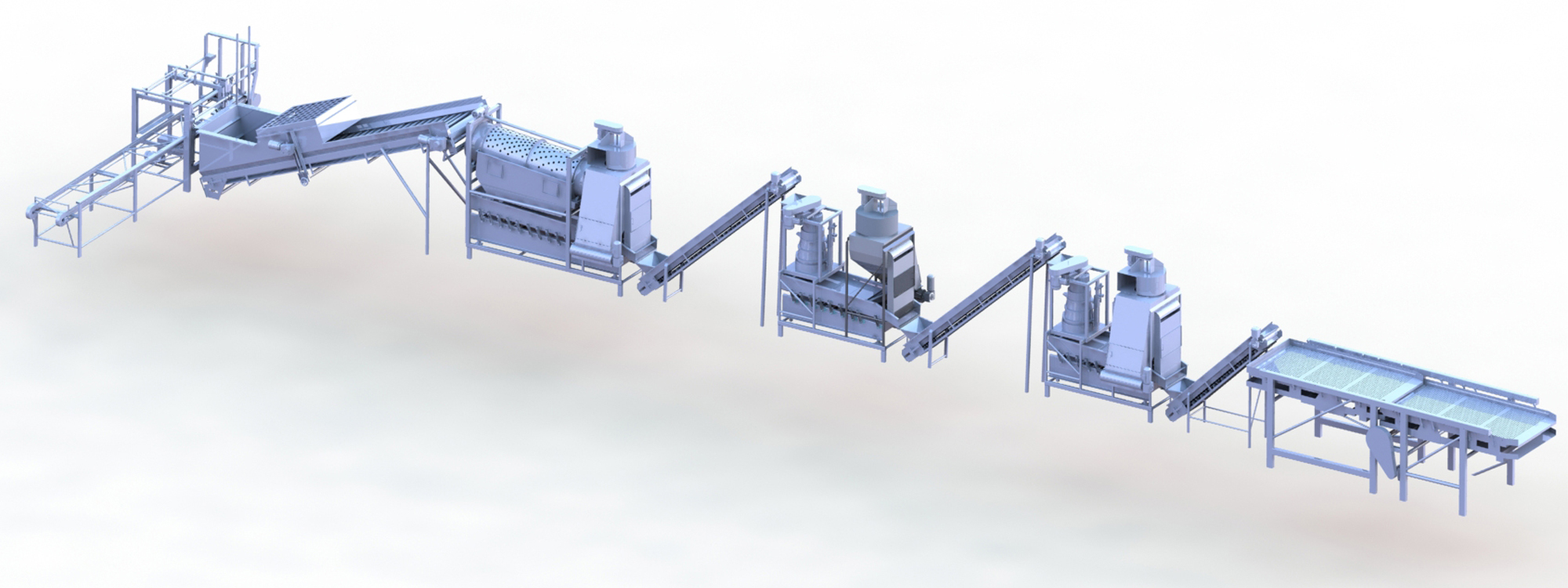

VWM Advanced Raisin Processing Washing and Packing Line

The VWM Advanced Raisin Processing Washing and Packing Line provides a thorough and complete washing and final defect removal prior to packaging.

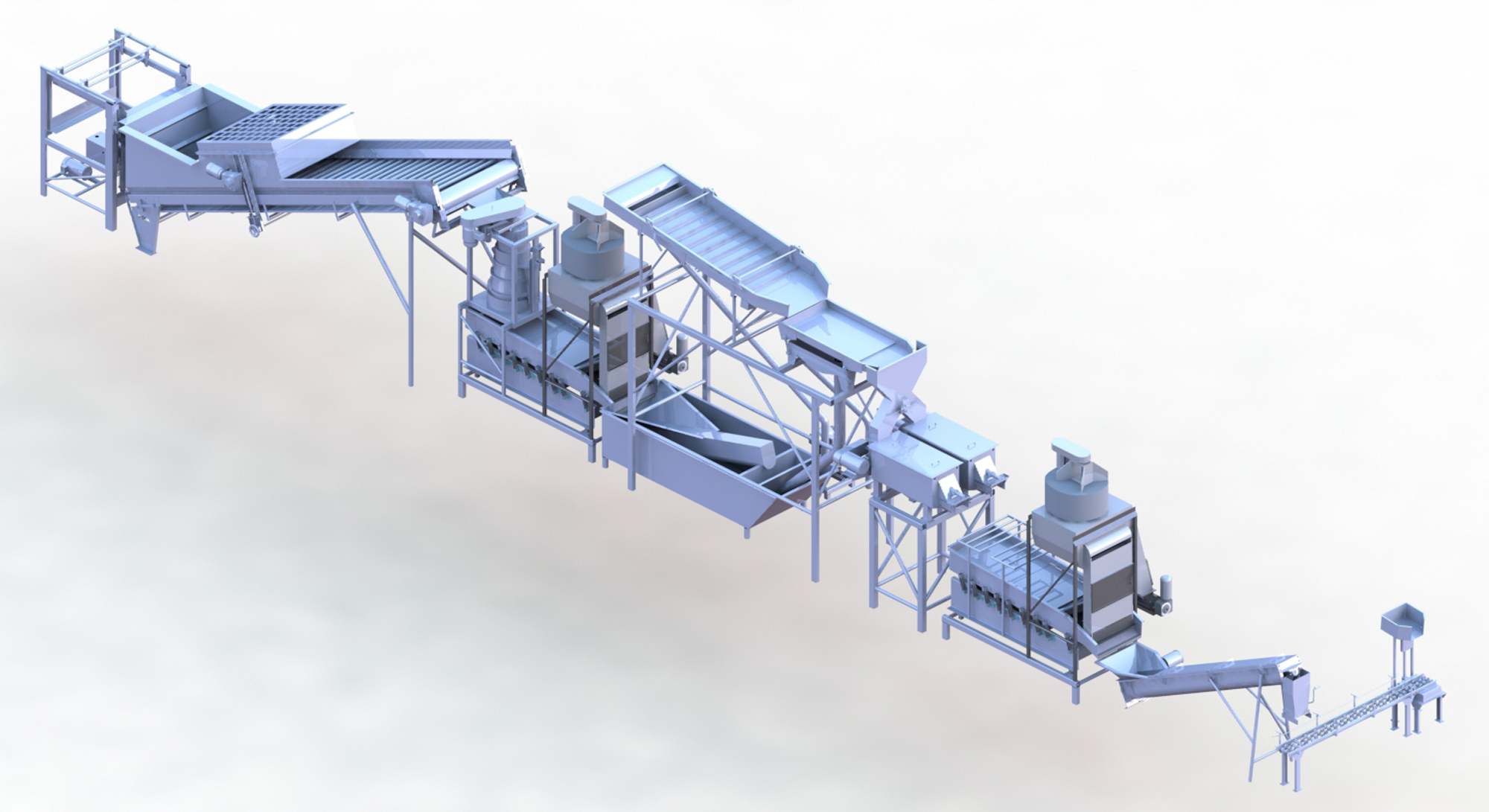

The VWM Deluxe Bin Dumper allows you to load and stage up to four full raisin bins to be conveyed, product dumped, and empty bins stacked for convenient unloading providing efficient, uninterrupted raisin processing.

The VWM Feeder Belt Conveyor controls the speed and capacity of product flow for the raisin line with its adjustable metering wheel which also breaks up any large raisin clumps.

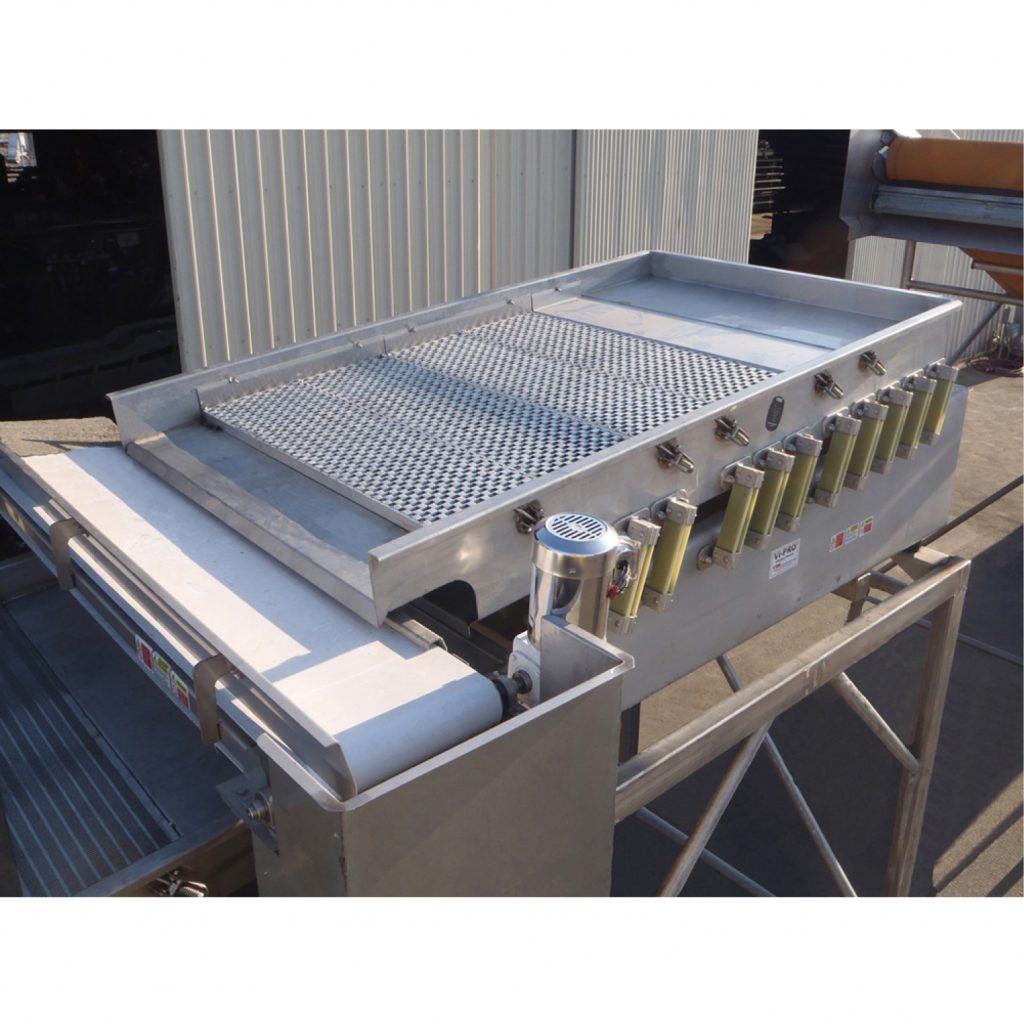

The VWM High Speed Scalping Vi-Pro® Vibratory Conveyor makes the initial removal of long stems and clumps.

The VWM SuperVAC® System with Fines Removal Vi-Pro® Vibratory Infeed Conveyor removes dirt, debris, smaller stems, and substandard raisins.

VWM‘s SuperVAC® System is designed to maximize efficiency of product cleaning and separation.

The VWM Fines Removal Vi-Pro® Vibratory Infeed Conveyor removes sand, dirt, and chaff from your raisins, and disposes it all neatly through a discharge chute into a bin.

The VWM Bucket Elevator is an efficient way to elevate product while minimizing valuable processing floor space.

The VWM Vi-Pro® Vibratory Size Grader efficiently sorts raisins through various sized screens of your selection. The sorted raisins are discharged into individual bins.

The VWM Vi-Pro® Vibratory Size Grader provides even product distribution for sizing efficiency.

VWM’s Vi-Pro® Washer provides a thorough and gentle wash to your product with sprays and specially designed screens.

VWM’s Wash Station is an effective way to remove rocks, dirt, and debris from your product.

The VWM Riffle De-Stoner removes rocks and then the De-Watering Vi-Pro® provides a fresh water, high pressure, rinse.

Low Capacity Raisin Processing

For those looking for lower capacity options.

VWM Advanced Raisin Processing offers customized machinery options for lower capacity lines

VWM Finish Watering Line

Advanced Raisin Processing Line Client Testimonials

Bob Miller | Facilities / Maintenance Manager

Mariani Packing Company

Valley Welding & Machine Works has partnered with Mariani Packing Company on numerous projects including design build fruit processing systems, proactive maintenance and turnkey equipment installations. Their after-sale technical, field service and spare component support is exceptional. We look forward to a continued successful association.

Kaz Yamaguchi | Corporation Manager of Fruits & Nuts Dept.

Kaz Yamaguchi | Corporation Manager of Fruits & Nuts Dept.

ShoEi Foods

The machinery we purchase from Valley Welding & Machine Works for our plants in Japan and China is reasonably priced and dependable. We do business with VWMworks because they give us the right information and advice when we need it right away.

Bill Danner | Maintenance Manager

Bill Danner | Maintenance Manager

Sun-Maid Growers of California

Valley Welding is a sound company to work with. They understand our unique needs and provide us with excellent service and support.